On is committed to igniting the human spirit through movement. Since its launch in 2010, this performance-driven sportswear brand has empowered millions of people to transform their sporting experience with premium shoes, apparel, and accessories.

Today, over 7 million athletes from 50 countries use On products, and demand for On shoes and clothing is skyrocketing. “We’re excited to experience tremendous growth,” comments Jiahui Yin, Chief Operating Officer. “However, to successfully transform from a startup into an international sportswear brand, it’s vital that we adapt our business processes to support seamless expansion.”

Spreadsheet-based finance, supply, and demand planning activities were a barrier to that seamless expansion, so On looked for a different approach. Specifically, the company aimed to bring all of its key data into a single repository to accelerate the reporting activities that it carries out at three- and five-week intervals.

Taking growth to new peaks

Following a recommendation from trusted partner Valantic, On replaced its spreadsheet-based financial planning processes with streamlined workflows in Anaplan. Next, the sportwear brand decided to use Anaplan to drive supply planning.

“Supply chains are still recovering from COVID-19 disruption and retailers are constantly having to adjust to other events that cause sudden and lasting market volatility,” says Yin. “In our sector, things can change fast and your ability to adapt just as quickly is key to staying ahead. Anaplan is very well-suited to meet the challenges of our industry because it can handle vast amounts of complex data. It offers planners the ability to update models on the fly when variables change—even if they change overnight.”

Measuring true performance

With Anaplan powering finance and supply planning, On has the timely and accurate forecasts it needs to scale its operations. What’s more, the company has reduced the time required to complete key planning activities by 88% since moving to Anaplan.

“When our data was siloed between teams and stored in different spreadsheets, it took two weeks to build a demand plan,” reflects Yin. “And creating a new business plan would then take a further three weeks. Now, all our teams and partners can input data directly into Anaplan, which means we’ve drastically reduced manual processes and cut the time to complete demand and business planning to under three days.”

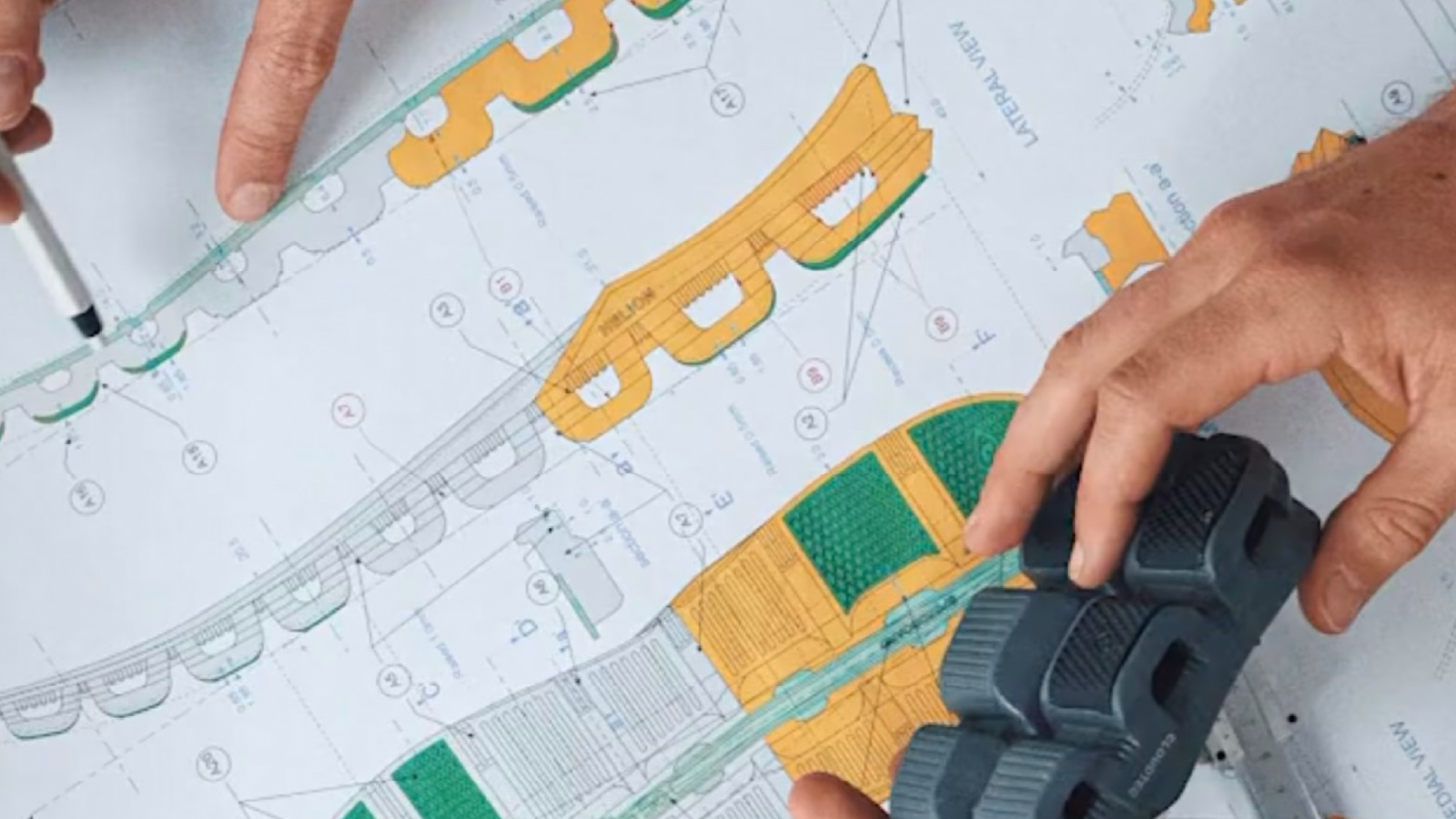

Freed from time-consuming, manual data collection and preparation, planners at On can now focus on higher-value work. For instance, in late September 2022, On launched a project to capture carbon emissions before they enter the atmosphere and use them as a raw material for its signature shoes—an initiative that required the company to reimagine the supply chain for key products. “We created CleanCloud—a foam for running shoes that’s derived from carbon emissions. Evaluating the raw materials we use in our shoes required us to look in detail at the impact of any changes on our supply chain, and using Anaplan as our one-stop solution for planning really gave us the flexibility we needed to drive this project.”

In that way, On’s Anaplan system supports the company’s greater mission. “Anaplan empowers us to do so much more than grow our business,” Yin Says. “It gives us the flexibility to innovate.”

On is optimizing its resources and striving toward the next level with Anaplan. “Great athletes are always looking for ways to push their boundaries and reach new limits, and we aim to give them an edge with our sportswear,” concludes Yin. “In the same way, Anaplan gives On an edge by helping us to achieve so much more with fewer resources—helping us plan for the next phase of our growth journey."